Valve locking systems HSV

Fittings and valves play a key role across a number of industrial production lines and energy networks. In these areas they perform important functions for safety and process control. For this reason, their correct setting and operation is decisive for the functional safety of entire systems.

In this regard, chains, padlocks and organisational measures such as Lockout-Tagout procedures (LOTO) do not offer sufficient protection against incorrect operation. The key to system and process safety: the use of valve interlocking systems.

Functionality and structure

Based on the safety requirements of your individual application, we will be happy to develop your own customised valve interlock system. We offer a broad range of various components for your valve interlock system.

The key to plant- and process safety

The valve interlocks as well as the keys are made of stainless steel. Individual coding guarantees the highest level of safety. It is not possible to have copies made of the keys (as can be done with simple padlock keys) due to the unique design and coding of each key.

The coded keys have been designed with ergonomics in mind and offer ease of use due to their shape, even when wearing heavy-duty safety gloves. There is no up or down position of the key. The coded keys can therefore be inserted into the lock from either direction. Inserting a key by just a few millimetres into the lock is sufficient to know that there is a correct match of key and lock.

These features guarantee a speedy workflow. Coloured tagging makes it easy to match the keys with the corresponding interlocks. Up to four lines of text are available for customer specific engravings.

What is a valve interlocking system?

Valve interlock systems provide a fail-safe system for the controlled opening and closing of valves. They are used whenever a specific opening and closing sequence for several valves is involved for the purpose of accident prevention, protection of materials, or guaranteeing process safety.

A simple and safe-to-use interlock system guarantees the best possible protection against physical injury and/or damage to assets or the environment.

Some typical applications for valve interlocks include:

- Oil and natural gas networks

- Pipelines

- Chemical production plants

- Tank storages

- Power plants

- Filling plants

- Paper mills

- Water supplies

A common application is, for example, the protection of presure safety valves (PSV) as shown in the following picture:

>> Click here for the full case study: Safeguarding of pressure safety valves (PSV)

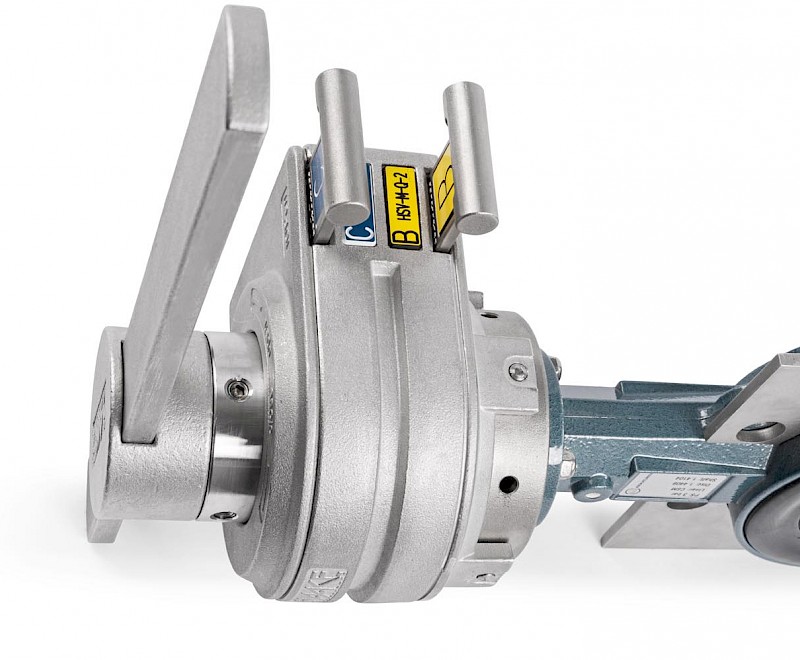

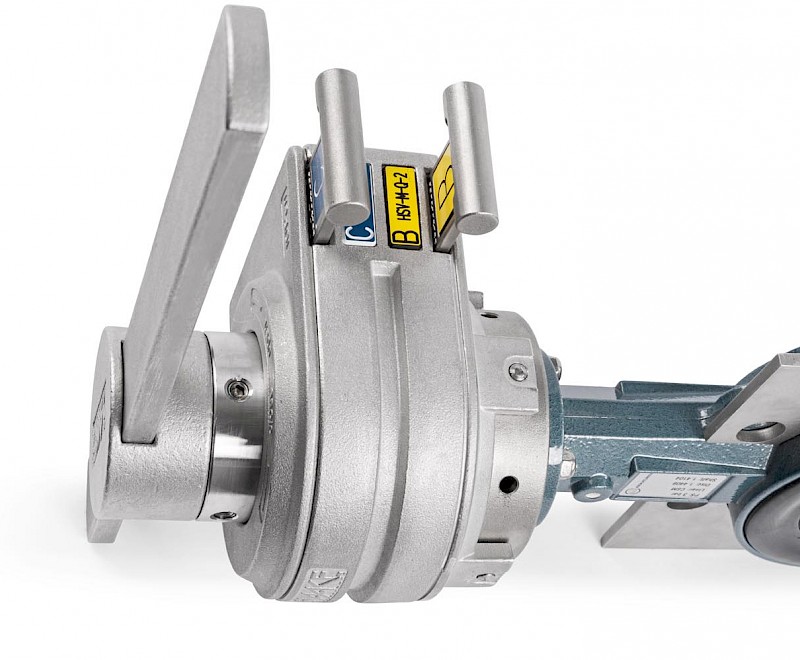

Valve interlocks HSV-Q

Valve interlocks HSV-Q are utilised for lever-actuated valves such as ball valves, shut-off valves and plug valves. All types of valves that operate with a 90° or 180° rotation can be fitted with HSV-Q valve interlocks.

Standard delivery includes a stainless-steel lever that is available in different lengths. The interlock can be perfectly aligned at different positions on the valve to guarantee optimal access to the key slots.

Valves that are already in operation can also be fitted retrospectively with HSV-Q valve interlocks without damaging or changing the valve fittings or seals.

During installation of the HSV-Q, the valve body remains unchanged; the existing lever is replaced as part of the valve interlock assembly includes a replacement ever which corresponds to the size of the original lever. The valve interlock can be supplied with either one or two operating keys depending on the type of system control required.

Valve interlocks HSV-R

Valve interlocks HSV-R are utilised for valves actuated by hand wheels such as slide valves, gate valves or gear box operated valves.

The number of rotations required for opening or closing varies depending on the type of valve. For this reason, the valve interlocks HSV-R are equipped with a count-release mechanism that adapts the locking action to the number of rotations required for corresponding final position. In this way, any valve position can be set as the locked open or closed position.

The valve interlock assembly includes a replacement hand wheel which corresponds to the size of the original hand wheel. The valve interlock can be supplied with either one or two operating keys depending on the type of system control required.

Anti-tamper locks HSV-AT

Anti-tamper locks HSV-M-AT protect against unauthorised actuation of valves, vandalism, or theft. This type of technology is currently used in petrochemical plants around the world. A mechanism in the body of the lock ensures that the lock rotates freely around the internal drive spindle of the body. No force is transferred to the spindle in this state and the valve cannot be operated. The coded key must be inserted to engage the drive spindle and hence to open or close the valve.

HSV-AT anti-tamper locks are suitable for any type of valve (ball, butterfly, gate, globe, gear box driven, slide valves etc.) and come equipped with either a lever or a hand wheel.

Locking device HSV-CL (Pig trap door locks)

The locking device HSV-CL is an integral part of a valve interlocking system that controls access to pig trap launchers and receivers. The valve interlock control system will ensure that all pressure and residual material is removed from the pig trap before the door can be opened.

Key change device HSV-X

The purpose of the HSV-X key exchange unit is to release or trap keys according to a pre-determined sequence and in accordance to the valve interlock system requirements.

The special HSV-X-HAST model combines the keys of the HSV valve interlocks with those of the HAST door interlocks by Haake Technik.

Key cabinet HSV-KC

The purpose of the HSV-KC key cabinet is to facilitate the local supervision and monitoring of valve interlock keys. Different cabinet sizes are available.

Every key slot on the cabinet is individually coded and assigned one matching key only. Colour codes and numbers make it easy to match the corresponding keys.

Overview of your benefits

- Ease to use: Your employees can learn how to operate the system quickly and easily, regardless of their qualifications. This increases acceptance and reduces the motivation for manipulation.

- Individually coded keys and locks with a high coding number: The operating sequence is predefined by the individual keys and locks. The risk of accidents due to bypassing or incorrect operation is reduced to an absolute minimum.

- Individual and difficult-to-copy key design and a controlled key providing by Haake Technik: We prevent the existence of uncontrolled spare keys within your system or application, which would allow the security function to be bypassed.

- Ergonomic key that can be inserted from both sides with early detection: The simple and transparent operation ensures a fast and trouble-free work process, thus increasing operator acceptance. In addition, early key recognition prevents potential damage to the lock and consequently reduces repair and maintenance costs.

- Mechanical, without wiring: Our system is easy and inexpensive to install and the security function is permanently guaranteed, i.e. even in the event of a power failure.

- Maintenance-free: Low maintenance and servicing costs

- Simple retrofitting is possible Systems that have already been supplied can easily be expanded or supplemented.

- Continuous closing: In case of a leakage, it may be necessary to operate the valve in the locked and closed condition. With the help of our valve interlocks with continuous closing feature, a valve that is locked in the closed condition can be closed further without a key, in order to close a leakage without going through the entire operating sequence.

Get advice from your international contact now!

Valve locking and key transfer system

In this example we want to change from one medium (orange) to the other medium (yellow). It shall be prevented that both media mix. Step 1: Key (A-red) is inserted into the right-hand lock (medium-orange) by the authorized employee. The right valve is closed. Key (B-blue) becomes free and can be removed. Step 2: Key (B-blue) is now inserted into the left lock (medium yellow). The left valve is opened and key (C-green) becomes free. This key is now removed by the authorized employee and can be used for further use.

To activate the YouTube video, you must agree to the marketing cookies.

Adjust consent