Safety edges HSC

Use of industrial machinery and equipment entails certain risks. A known safety risk: pinch points, as well as shearing and crushing edges. Failure to secure them properly can lead to injuries - for example, by catching an employee's hand. So-called safety edges were developed to prevent exactly this type of injuries.

What is a safety edge?

Safety edges are contact-sensitive detectors that recognise whenever a person or part of a person's body comes into contact with the detector. Should a safety edge register a contact or an obstacle, the automatic drive of the machine is immediately stopped.

We encounter safety edges frequently in our everyday lives, but it's a rare occasion that we actually notice them. For instance, when we pass through the revolving door in an airport, a safety edge ensures that our arm or leg is not caught or crushed between the frame and the wing of the revolving door.

You can find many different types of safety edges on the market. Besides electrical systems that operate based on the closed circuit principle there are optoelectronic systems as well. These types of safety edges require a special control unit to process the signals from the safety edge. The Haake safety edges work based on the highly effective and reliable normally closed contacts principle. It does not require a special control unit.

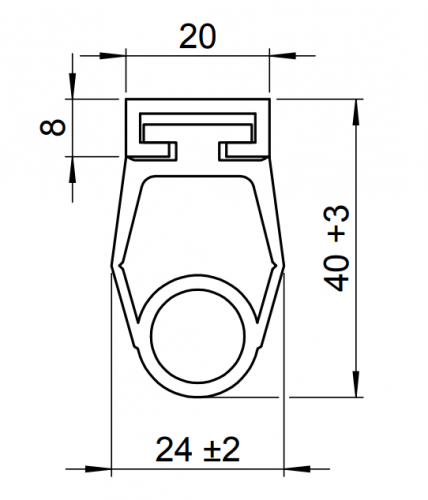

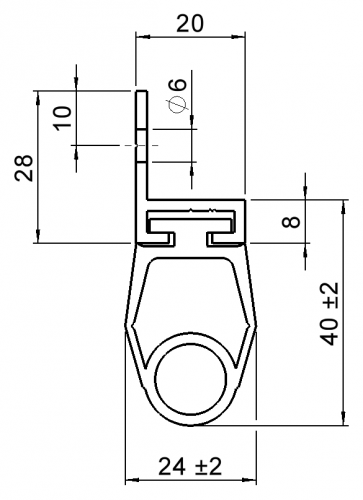

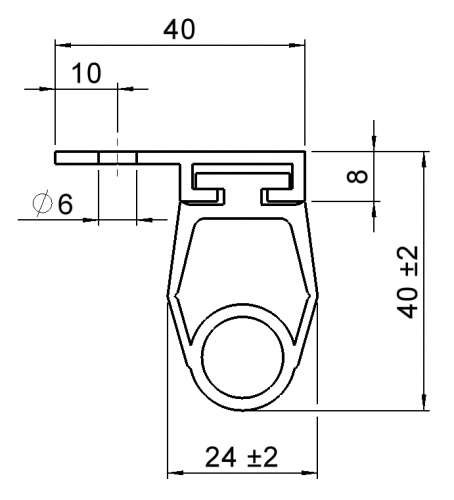

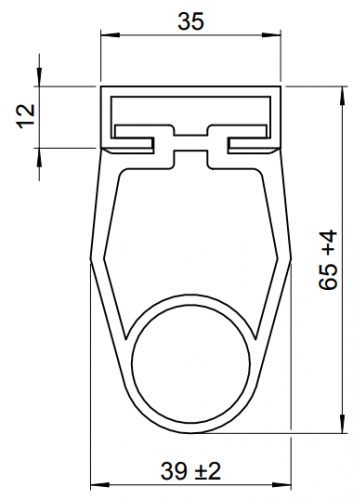

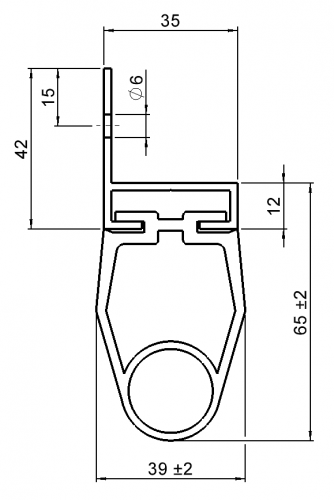

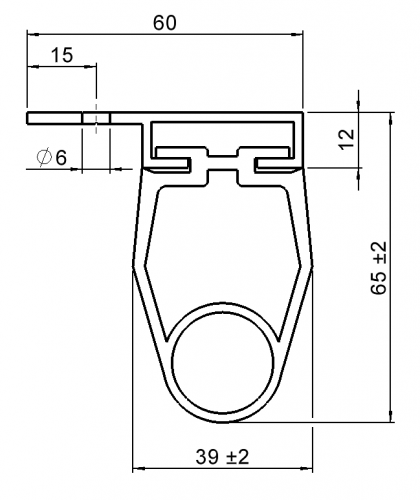

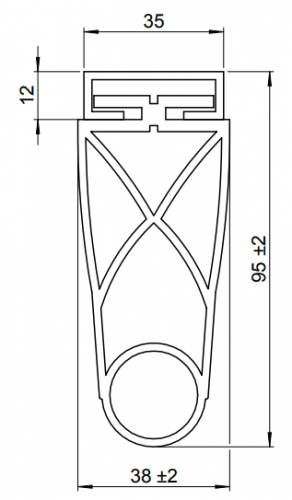

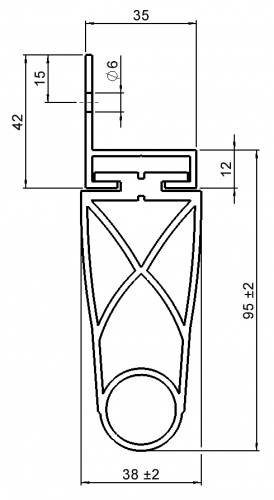

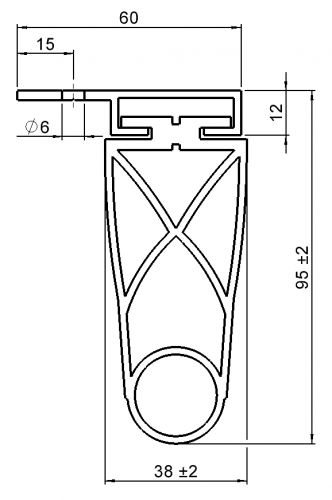

Functionality and structure

The core element of our safety edge HSC is the Haake contact chain. It consists of electrically conductive contact rolls and intermediate insulating elements connected in series. These are arranged alternately along an expander cord. With the help of pre-tension force, the contact rolls are pressed together; and the closed circuit is completed. When activated, at least one of the contact roll pairs is isolated with the wedge-shaped insulating spacers. This breaks the closed circuit. Conversion of the output signal is therefore unnecessary, as a break contact signal is transmitted directly to the relevant emergency stop module of the secured machine.

Optimal switching performance - minimal force required to trigger the switch and short feedback signal paths

The Haake contact chain is located in the frontal part of the safety edge. The breaking of the contact points is not based on deflection of the contact chain, but rather on deflection of the external radial forces into internal axial forces. Activation triggers a switch-off action even at low switching forces via an extremely short feedback signal path. The entire remaining height of the safety edge profile can be used for overtravel. Large overtravel distances is an immensely important feature of a safety edge, above all with respect to prevention of injuries. Due to rotationally symmetrical structure of the switching elements, the triggering of the contact chain signal is independent from the direction of activation.

Safety edges customised for your individual requirements

This simple but highly effective operating mechanism of our safety edges provides for a wide range of application scenarios. Here is just a small selection of the machines and systems which use our safety edges HSC:

- Machine hoods

- Automatic doors and gates

- Lift tables

- Packaging machines

- Industrial trucks

In addition to a standardised range of safety edges, we offer a large number of variations, which we develop and manufacture for you according to your individual safety requirements and application.

Our safety specialists will be happy to assist you!

You can find out how we have safeguarded dangerous shearing and crushing edges in lifting and conveying technology with our Haake safety edges HSC® here:

>>Safeguarding shearing and crushing edges in lifting and conveying technology

Overview of your benefits

- Highest safety standards: our safety edges meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short signal feedback paths. Triggering of the contact chain signal independently from the direction of its activation.

- Customisation: wide range of safety edges to suit your individual safety requirements and application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our safety edges are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your machine or equipment.

Get advice from your international contact now!