Foot protection switch HFS-FS®

Handling pallet trucks is associated with an increased risk of injury: In 2022 alone, there were more than 3,000 accidents involving industrial trucks. The operators of the material handling equipment themselves are most frequently affected. 45% of accidents result in ankle and foot injuries. The most common causes of accidents are collisions or overrunning, as well as becoming trapped between the industrial truck and surrounding structures such as walls or pallets. These incidents occur in particular when driving or maneuvering in the direction of the drawbar (DGUV 2022).

The consequences of such accidents are not only painful, but also costly: those affected often have to take between 11 and 20 days off work. Accidents occur regardless of the manufacturer or type of industrial truck.

How the Haake Foot Protection Switch HFS-FS® works

A highly sensitive, touch-sensitive sensor is integrated into the HFS-FS® foot protection switch for pallet trucks, which recognises contact with a part of the body. If contact or an obstacle is detected, this additional foot protection for lift trucks reacts immediately: it does not only stop the pallet truck, but also initiates a brief reverse movement. This function makes a significant contribution to preventing injuries that can be caused by running over or crushing the foot. The HFS-FS® Foot protection switch therefore significantly increases occupational safety when handling pallet trucks.

The Haake safety edges HSC® and the Haake Safety Bumpers HSB are unsuitable for this type of application. The forces that occur would irreversibly deform the installed contact elements after a short time and rule out any further use. Furthermore, users should be able to maneuver pallet trucks easily between racking and narrow pallets. The use of the Haake Safety edges HSC® or the Haake Safety Bumper HSB with a minimum height would not fulfil the desired requirements with regard to the operation of pallet trucks in this context.

How the Haake Foot Protection Switch HFS-FS® works

To activate the YouTube video, you must agree to the marketing cookies.

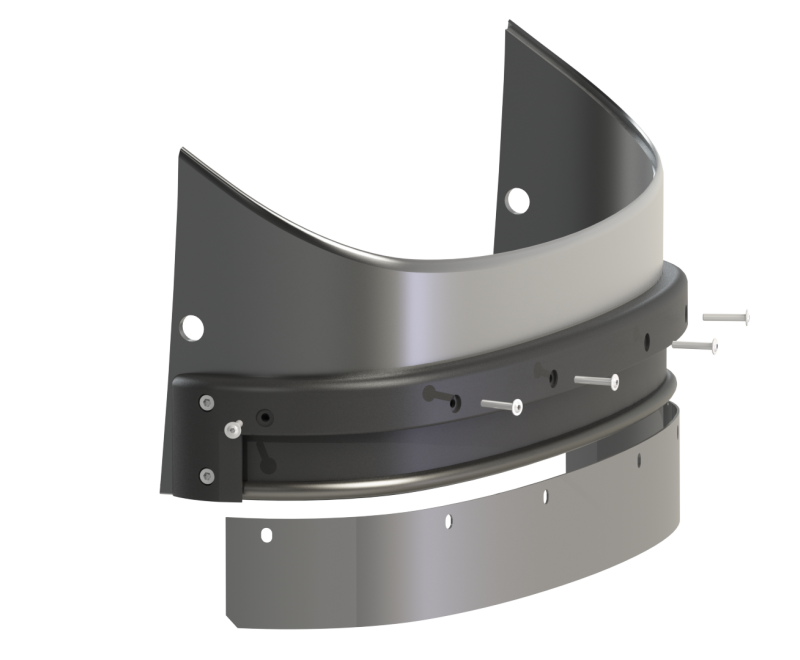

Adjust consentStructure of our Foot protection switch HFS-FS

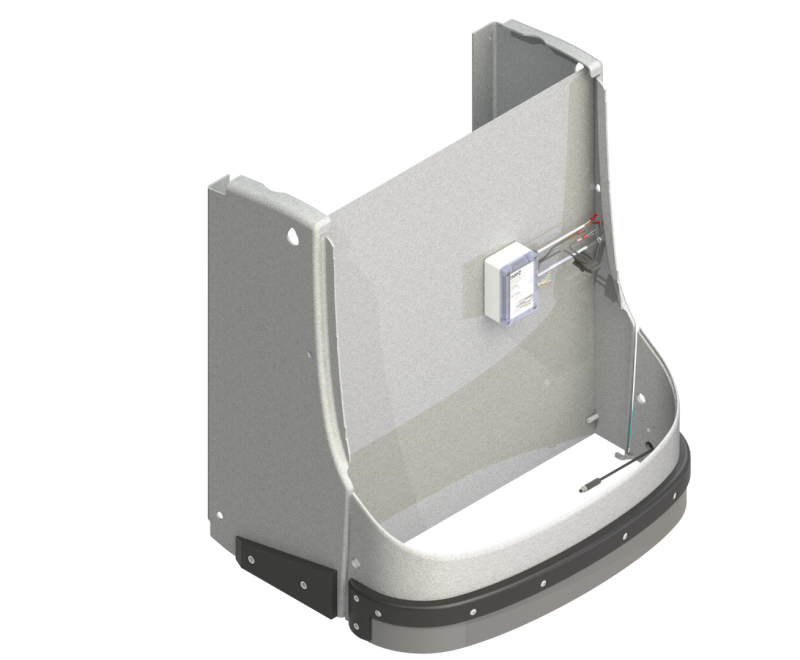

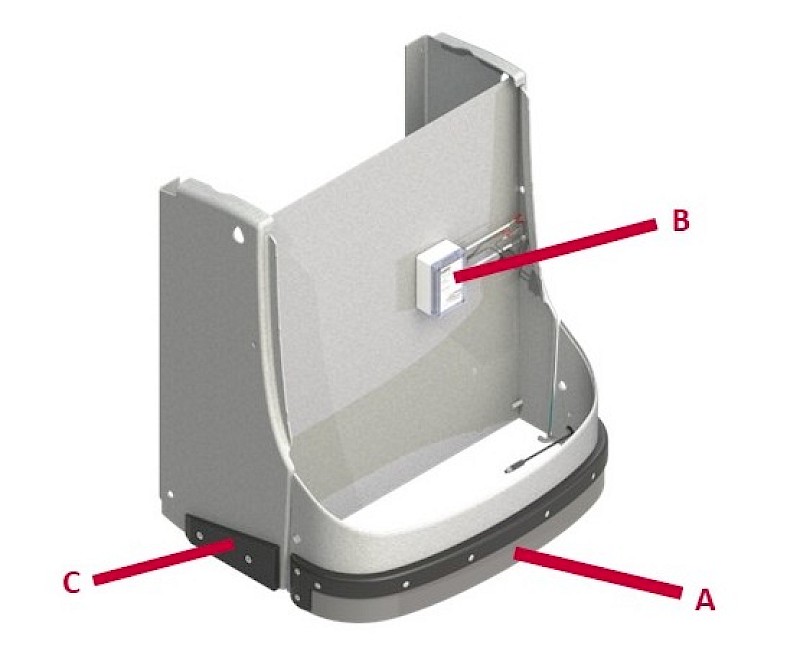

The HFS-FS® foot protection switch for industrial trucks is used to interrupt circuits, designed for a range of industrial trucks such as hand-guided, pedestrian-controlled and pedestrian-controlled low and high lift trucks. The HFS-FS® foot switch is not only customisable in terms of its dimensions and shape, but also has the same basic design. The following components are integrated:

Area sensor [A]: The are sensor is the centrepiece of the foot protection bar for industrial trucks. When pressure is applied, i.e. when the operator activates the switch, the signal supplied by the sensor changes.

Controller [B]: The controller processes the signals of the area sensor. It converts the data received from the sensor into safety-relevant signals that lead to the interruption of one or more circuits. Two integrated LED indicator lights show the operating status through a transparent cover. The buzzer integrated on the circuit board is activated if the sensor fails. This allows the proper functioning of the foot protection bar for pallet trucks to be checked at any time.

Lateral deflector kit (optional) [C]: The vehicle-specific deflector kit extends the availability of the area sensor. It consists of a left and a right deflector as well as the required fastening material. The deflector is designed to absorb lateral forces on the foot protection bar for industrial trucks.

Foot Protection Switch HFS-FS® for pallet trucks and your benefits at a glance

- Occupational safety when handling industrial trucks: Reducing the risk of accidents when handling pallet trucks

- Reduce labour costs: Reduction of accident-related absences and labour costs in the company

- Increase satisfaction: Safe working environment and satisfied operators

- Adaptability: The foot protection switch for pallet trucks can be adapted to almost any vehicle contour

- Cost savings: Simple replacement of defective parts thanks to the HFS-FS® smart spare part concept

Download Flyer HFS-FS Foot protection switch

Get advice on Foot protection switch HFS-FS® from your international contact now!

The smart spare parts concept of the Haake HFS-FS Foot protection switch for pallet trucks

The signalling profile makes it easy for vehicle manufacturers to replace the sensor, thus significantly reducing spare part costs for the end user. The sensor is available as a spare part. In addition, the controller, 3-pin plug, deflector plate and lateral defelctor kit is also available as a spare part and can be replaced directly at the vehicle without having to lift the pallet truck.