Realizing collaborative robot safety

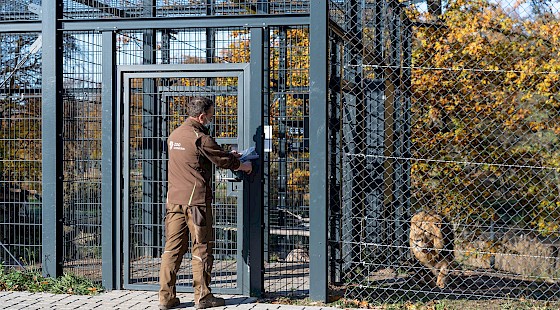

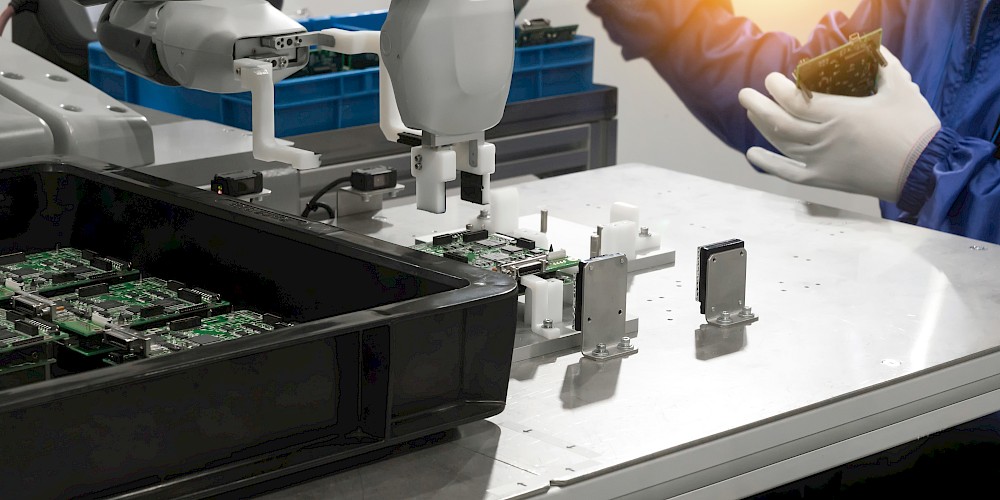

Human-robot collaboration (HRC) is considered one of the most important trends in industrial manufacturing. Today, collaborative robots are already being used in large numbers to support humans in monotonous or strenuous tasks. The special feature: Humans and robots share their workspace. Human safety is a particular challenge in this context and its assurance is regulated by guidelines and standards such as the DIN ISO/TS 15066.

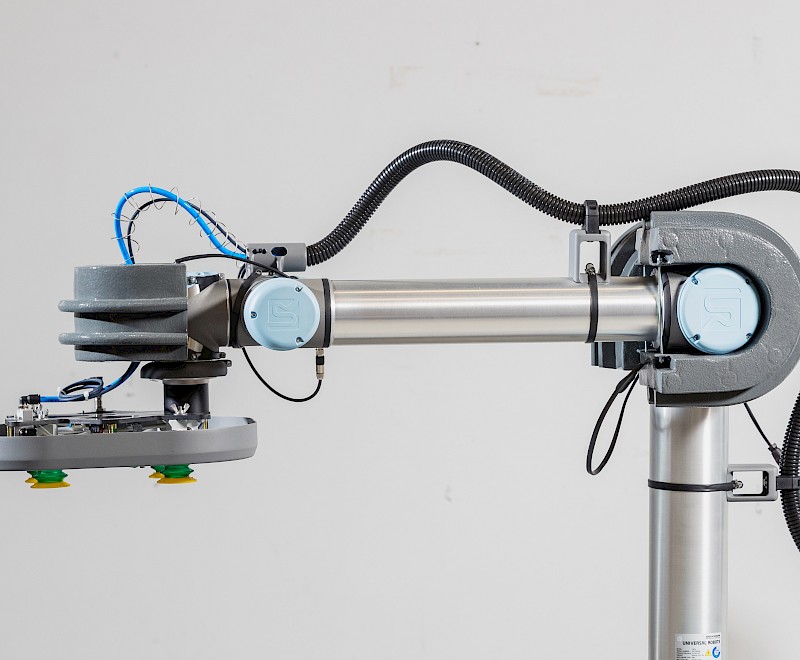

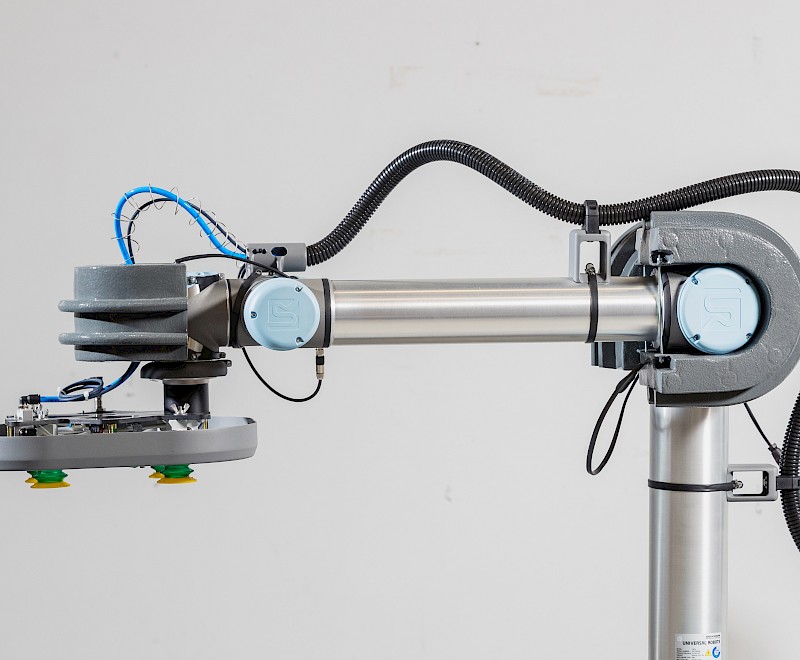

Haake Technik has specialized in the protection of collaborating robots with the help of contact-sensitive sensors such as safety edges, switching buffers and step mats. These specially developed tactile sensors detect contact with a person or part of a person's body and ensure that the automatic drive of the robot is switched off immediately in case of contact.

Development of a customized safety bumper - an application example

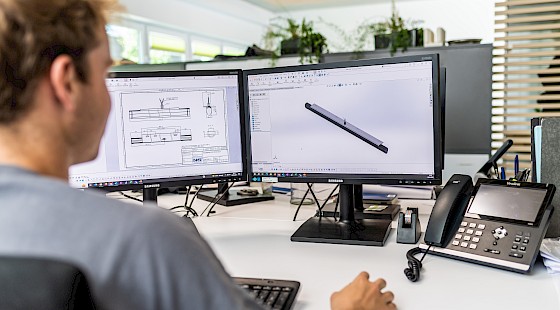

With our standardised cross-sections and materials we are able to cover a large number of potential applications. For particularly challenging applications we develop customised safety solutions that are tailored to your individual requirements and wishes in terms of dimensions, shapes, colouring and the materials used.

Together with our customer FlexLink AB, we have developed such a special version of our HSB safety bumper for the safeguarding of a collaborative palletising robot. This custom-made safety bumper meets both the individual and application-specific requirements as well as the normative specifications. The following video illustrates how the safe interaction with the collaborative palletising robot is realized in practice.

To activate the YouTube video, you must agree to the marketing cookies.

Adjust consentOverview of your benefits

- Highest safety standards: our bumpers meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short feedback signal paths Depending on the application, various contact chains are used to achieve an optimal switching behaviour.

- Customisation: a wide range of dimensions, shapes and colours are available depending on your specific application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our bumpers are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your collaborative robot.

Get advice now from your regional contact now!