Safeguarding Automated Guided Vehicles

Safeguarding Automated Guided Vehicles

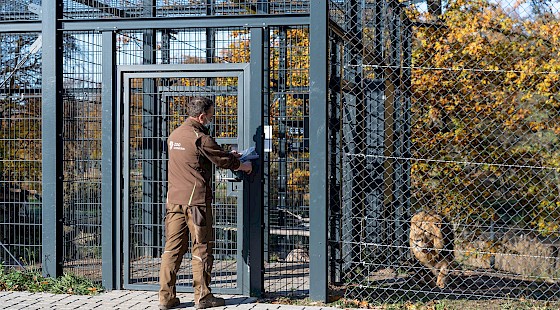

In logistics, automated guided vehicles are used that are specially designed for the efficient and safe transport of goods. Such conveyor systems must be safeguarded against collisions to protect people.

To safeguard such applications, we have been developing and supplying high-quality and innovative HSB safety bumpers for over three decades. These are touch-sensitive sensors that recognise contact with a person or parts of a person's body. If a bumper detects contact or an obstacle, the machine's automatic drive is switched off immediately.

Development of customised safety bumpers for our customer DS Automotion - an application example for the safeguarding of automated guided vehicles (AGV)

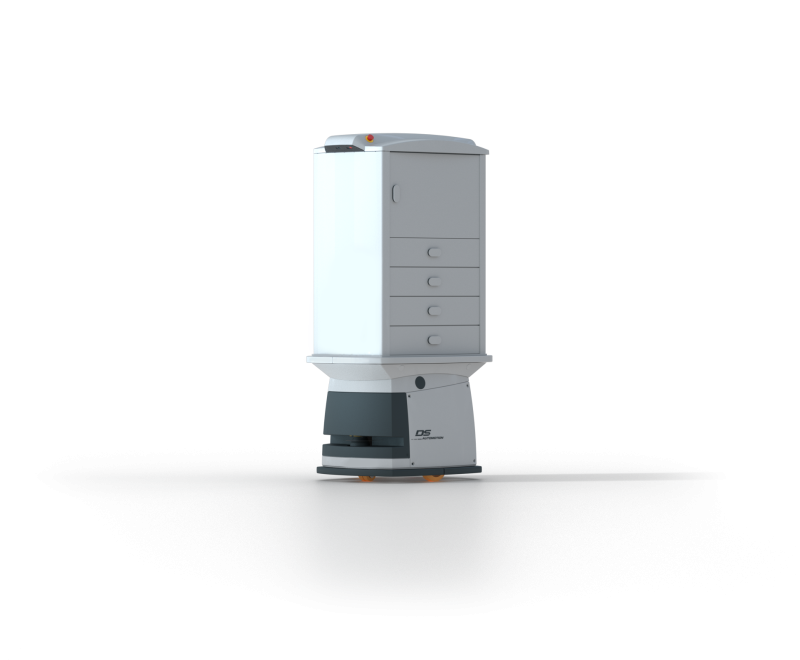

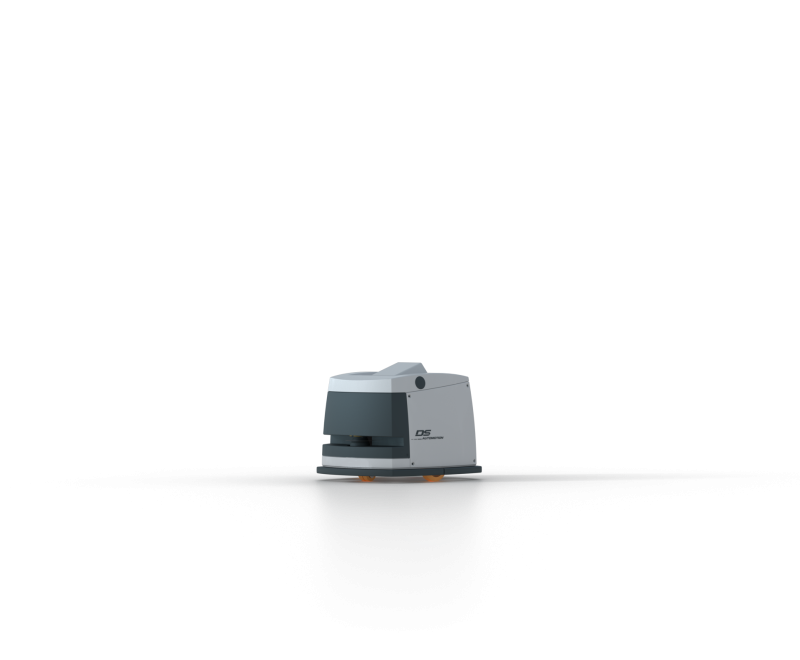

To effectively relieve the healthcare staff, our long-standing customer DS Automotion developed the innovative mini automated guided vehicle (AGV) "Sally". The Sally is specially designed to transport sterile goods, deliver documents and distribute medication directly to the hospital wards. The Sally performs these tasks independently, allowing smooth interaction between man and machine.

For guaranteeing the safety of healthcare staff and patients, our HSB bumpers are mounted on the vehicle. The integrated tactile sensors in the bumper detect contact with people or obstacles and transmit the signal, stopping the movement of the vehicle immediately. As a result, the Sally contributes to the efficient and safe assistance of healthcare staff.

To activate the YouTube video, you must agree to the marketing cookies.

Adjust consentOverview of your benefits

- Highest safety standards: our bumpers meet category 3 and performance level d requirements in accordance with DIN ISO EN 13849-1.

- Optimal switching performance: minimal force required to trigger the switch and short feedback signal paths Depending on the application, various contact chains are used to achieve an optimal switching behaviour.

- Customisation: a wide range of dimensions, shapes and colours are available depending on your specific application.

- Cost reduction: you do not need to purchase a special control unit as the Haake contact chain features normally closed contacts allowing the signal to be processed directly. Besides a simple financial advantage, it also eliminates the need for complex connection and wiring work.

- Conformity: all our bumpers are manufactured in accordance with the Harmonised Standards and therefore meet all requirements of The Machinery Directive 2006/42/EC.

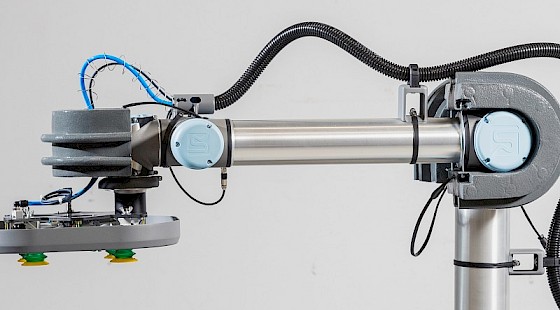

- Plug and play based on customer specifications: safety edge is connected directly to the available emergency stop module of your collaborative robot.

Get advice now from your regional contact now!