Case study: Safeguarding pigging station

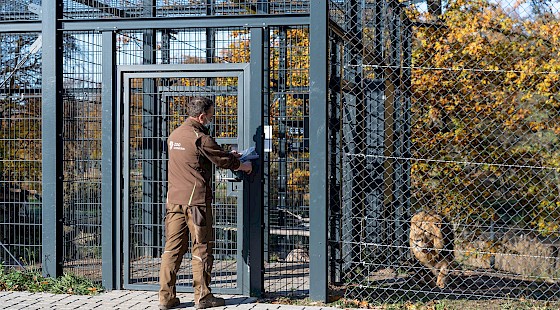

Normally, cleaning pigs are used to clean pipelines. Equipped with brushes or other scraping devices, these pigs remove dirt and other debris as they move through the pipelines. These are brought into the pipeline through a pig trap and transported through the pipes using pressure. Our Valve interlocking systems HSV® are used to ensure that this pig trap can only be opened when it is in safe condition.

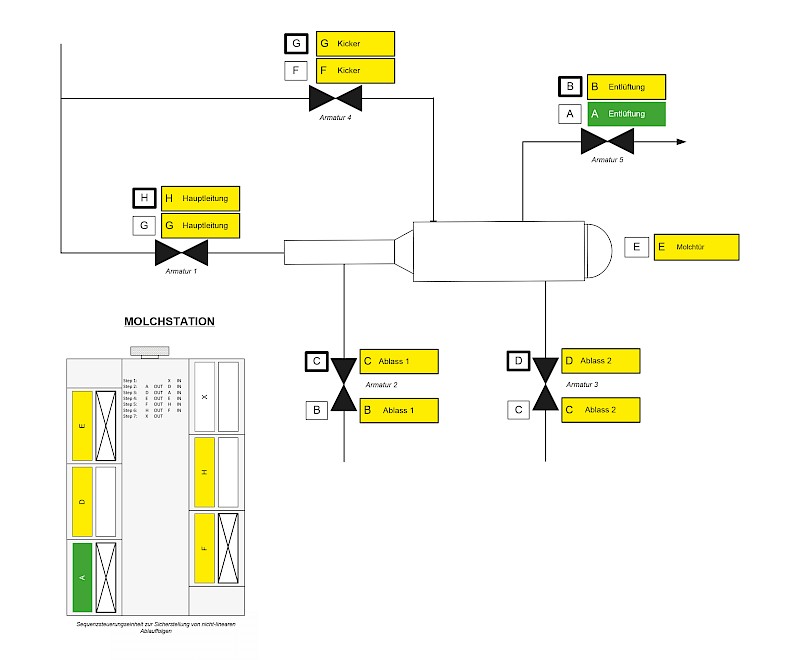

Such pigging systems are often more complex to operate and contain a number of valves and operating steps. To be able to cover non-linear sequences, so-called Sequence Control Units are used in pigging systems.

With the help of this unit, the predefined, safe sequence of operation is strictly adhered to, as the keys for operating further valves are only released when the previous steps habe been completed. This ensures that the operator can only open the pig trap closure door when it is depressurised. A special, customised design of our HSV-CL component is used to safeguard the closure door. Even motor-operated valves, that are often used in the main lines of such pigging systems, can be integrated into the key interlocking sequence using a specialised set of interlocks. Therefore, the Valve Interlocking System HSV® provide a complete solution for securing the pigging process at site.

Overview of your benefits

- Ease to use: Your employees can learn how to operate the system quickly and easily, regardless of their qualifications. This increases acceptance and reduces the motivation for manipulation.

- Individually coded keys and locks with a high coding number: The operating sequence is predefined by the individual keys and locks. The risk of accidents due to bypassing or incorrect operation is reduced to an absolute minimum.

- Individual and difficult-to-copy key design and a controlled key providing by Haake Technik: We prevent the existence of uncontrolled spare keys within your system or application, which would allow the safety function to be bypassed.

- Ergonomic key that can be inserted from both sides with early detection: The simple and transparent operation ensures a fast and trouble-free work process, thus increasing operator acceptance. In addition, early key recognition prevents potential damage to the lock and consequently reduces repair and maintenance costs.

- Mechanical, without wiring: Our system is easy and inexpensive to install and the safety function is permanently guaranteed, i.e. even in the event of a power failur.

- Maintenance-free

- Simple retrofitting is possible: Systems that have already been supplied can easily be expanded or supplemented.

- Continuous closing: In case of a leakage, it may be necessary to operate the valve in the locked and closed condition. With the help of our valve interlocks with continuous closing feature, a valve that is locked in the closed condition can be closed further without a key, in order to close a leakage without going through the entire operating sequence.

Get advice from your regional contact now!